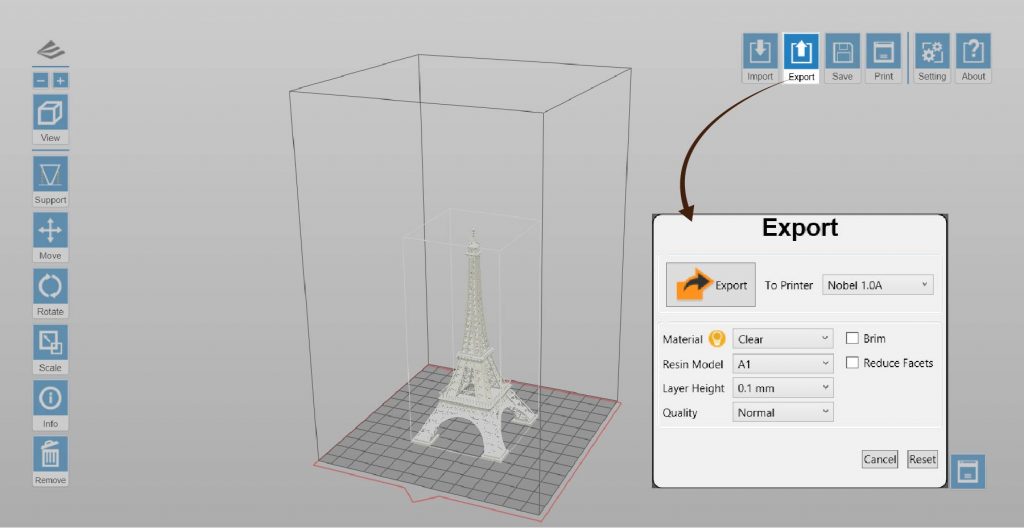

Совместимый Принтер: Nobel 1.0A

Модель смолы: C1

Литьевая смола схожа по свойствам с воском. После выплавки она не оставляет пепла и подходит для литья по выплавляемым моделям, что позволяет сократить количество операций, например, исключив вырезание моделей из воска, используемое в традиционной технологии.

Советы по созданию моделей

По свойствам литьевая смола схожа с воском: оба материала мягкие и ломкие, то есть распечатанный предмет может легко сломаться под воздействием растяжений, возникающих в процессе печати. Следуйте советам по моделированию дизайна ниже для оптимизации печати.

» Минимальный диаметр вертикального прутка ≥0,8мм

» Параметры других функций перечислены в общем руководстве по проектированию.

Примечание

» Данные рекомендации применимы для толщины слоя 0,1 мм.

» Для удержания на платформе предметов крупнее 60x60x120 мм или тяжелее 10 г может потребоваться больше опор.

Рекомендации по конфигурации печати

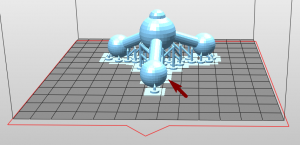

Как и при печати обычной смолой, если у модели имеются нависающие элементы или у нее маленькая площадь контакта с платформой, для полной печати предмета требуются дополнительные опоры.

В программе XYZware_Nobel предусмотрена функция автоматического построения опор, которая анализирует модель и автоматически формирует поддерживающие опоры. Иногда может потребоваться в ручном режиме добавить дополнительные опоры, чтобы обеспечить адгезию предмета к платформе.

Нажмите здесь, чтобы ознакомиться с инструкциями по применению опор и описанием их функций.

Если печать не удается, измените расположение предмета, измените угол его разворота и конфигурацию поддерживающих опор.

Рекомендованный процесс выплавки

При литье по распечатанным моделям руководствуйтесь температурными показателями, приведенными на следующем графике, чтобы обеспечить полную выплавку смолы и получить литой предмет с безупречно гладкой поверхностью.

Рекомендации по финишной обработке

Чистка

После удаления распечатанного предмета с платформы очистите его этиловым спиртом концентрацией не менее 95%. В процессе чистки рекомендуется с помощью сита полоскать распечатанный предмет в спирте, чтобы удалить остатки смолы с его поверхности.

После чистки с помощью сита извлеките распечатанный предмет из спирта и дождитесь испарения спирта с поверхности предмета.

Примечание

» Так как эта смола хрупкая, не чистите распечатанный предмет с помощью щетки. Так можно поцарапать поверхность предмета.

» Не погружайте распечатанный предмет в спирт дольше чем на 10 минут, так как спирт может разъесть поверхность предмета и повредить его.

» После погружения распечатанного предмета в спирт он может потускнеть, это нормально. Выцветание не повлияет на результат литья.

Высушите спирт на поверхности распечатанного предмета естественным способом

После промывки распечатанного предмета на его поверхности останется спирт.

После промывки не перемещайте распечатанный предмет и не выполняйте финальное отверждение до тех пор, пока с его поверхности полностью не испарится спирт. После испарения спирта, внимательно отыщите любые остатки смолы на распечатанном предмете. Обязательно удалите неотвердевшую смолу, чтобы она не испортила элементы исходной модели.

Примечание

» Если выполнить отверждение при наличии остатков спирта на поверхности распечатанного предмета, его поверхность станет белой и мутной, что может ухудшить результат литья.

Совет

» После погружения в спирт распечатанный предмет несколько выцветет. После испарения спирта естественным образом предмет снова приобретет исходный светло-оранжевый цвет. То есть по цвету распечатанного предмета можно определить, испарился ли спирт.

Удаление опор

Отрежьте опоры с помощью инструментов, но не тяните за них (потянув за опору, можно повредить поверхность объекта).

Финальное отверждение

Распечатанный предмет из литьевой резины должен пройти финальное отверждение с помощью УФ-излучения, что придаст ему необходимую твердость для литья по выплавляемой модели.

Нажмите здесь, чтобы узнать о профиле отверждения в УФ-камере XYZprinting (модель: 3UD10).

Рекомендация

» При длине волны УФ-излучения 375~405 нм, интенсивности излучения 0,9–1,8 Дж/см² и толщине элементов предмета более 7 мм рекомендуемая длительность финального отверждения составляет 10 минут.

Хранение неотвержденной смолы

Неотвержденную смолу в кювете для смолы не следует подвергать воздействию света. Неотвержденную смолу можно хранить в непрозрачном контейнере, предварительно отфильтровав. Пред следующей печатью снова вылейте эту смолу в кювету для смолы.

Примечание

» Для хранения смолы рекомендуется использовать непрозрачный полипропиленовый контейнер.

» Nobel 1.0/1.0A - Standard resin » Nobel 1.0/1.0A - Flexible resin » Nobel 1.0A - Castable resin » Nobel Superfine - Standard resin » Nobel Superfine - Castable resin

“Utilities” menu provides the control of the printer. You can instruct to fill the resin tank manually, and calibrate the printer when necessary.

“Utilities” menu provides the control of the printer. You can instruct to fill the resin tank manually, and calibrate the printer when necessary.